Products

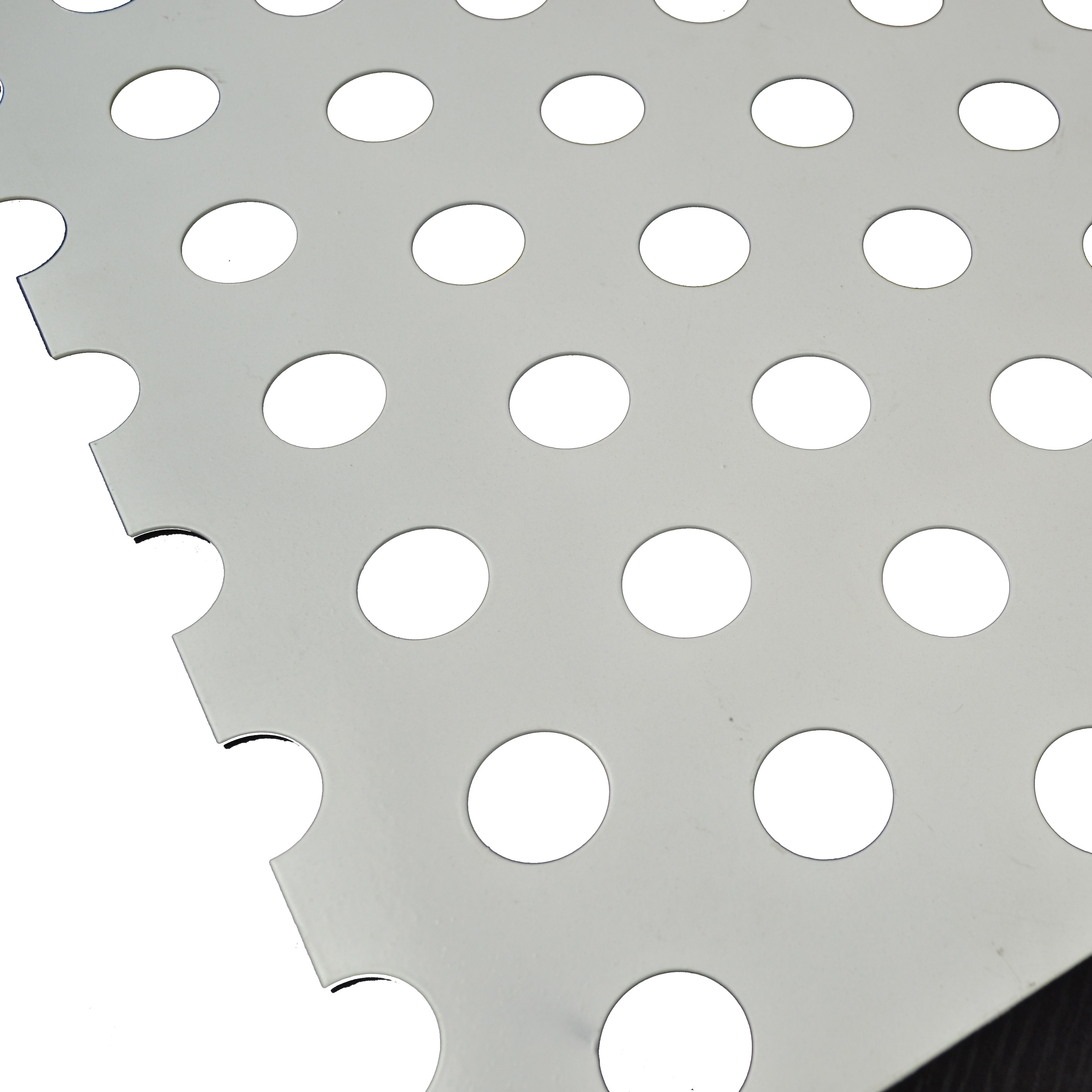

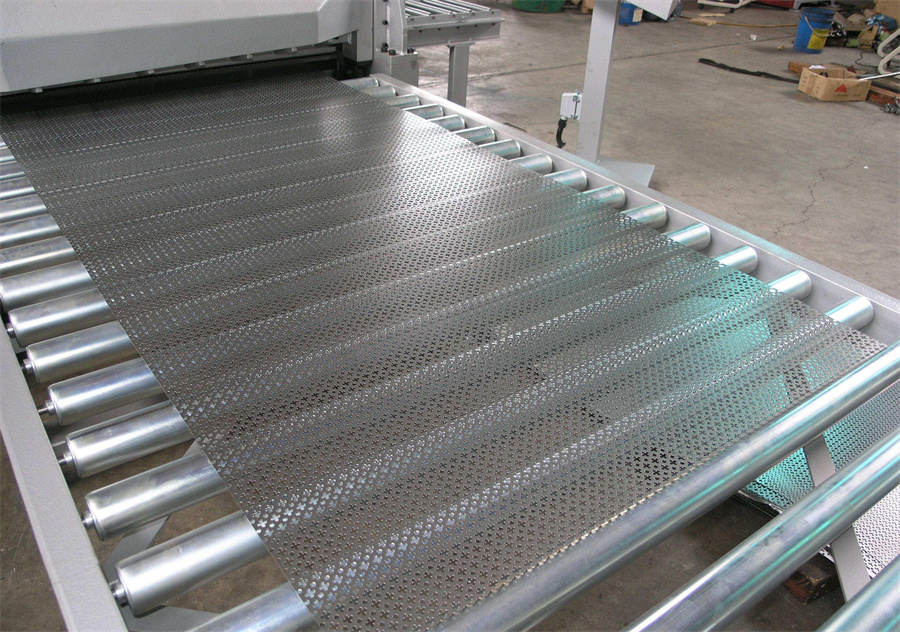

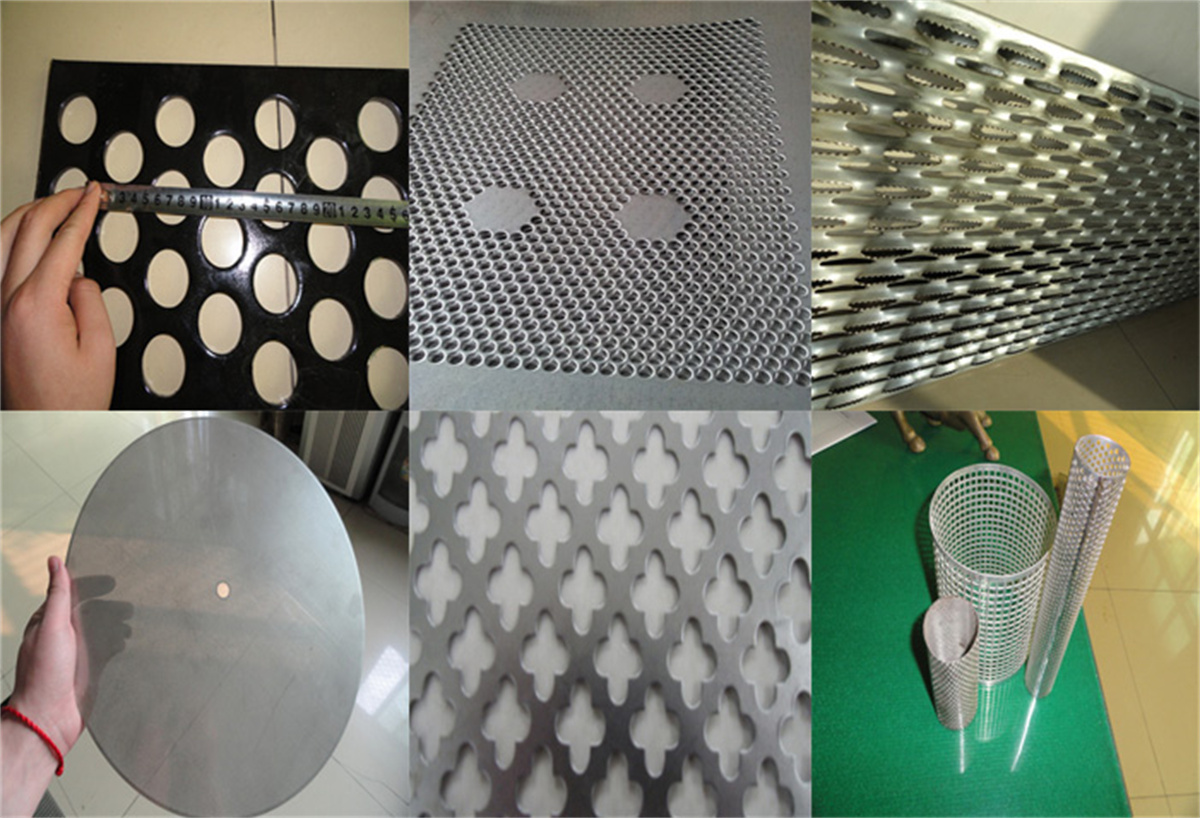

Perforated Metal Sheet for decorative sound equipment

Basic Information

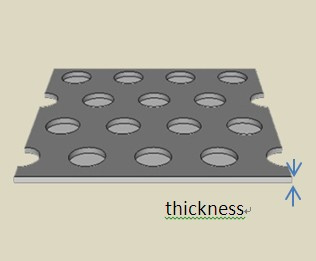

Thickness or Gauge

Thickness of the metal sheet do not change during the perforation.

Normally thickness is expressed in gauge. However, to avoid possible Thickness misunderstanding, we would suggest to express them in inches or millimeters.

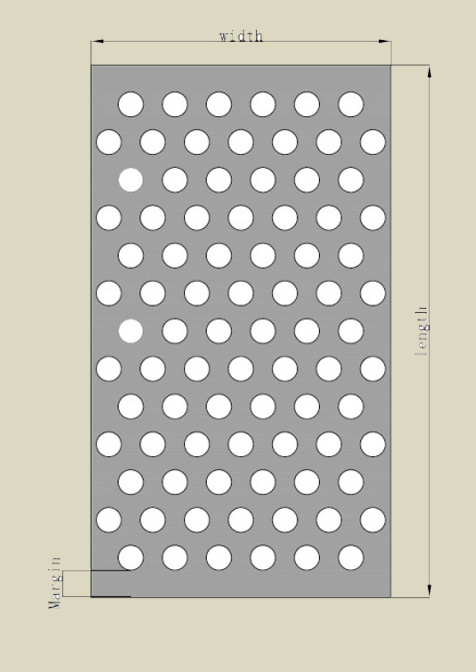

Width and Length

The most common width and length are as following:

- 1000mmX2000mm

- 1220mmX2440mm

- 1250mmX2500mm

- 1250mmX6000mm

- 1500mmX3000mm

- 1500mmX6000mm

However we also do other sheet size according to customers’erquirements.

Margins

Margins are the blank (un-perforated)area along the edges of the sheet. Normally the margin on the length are 20mm minimum, and margin along the width can be 0 minimum or at customers’requests.

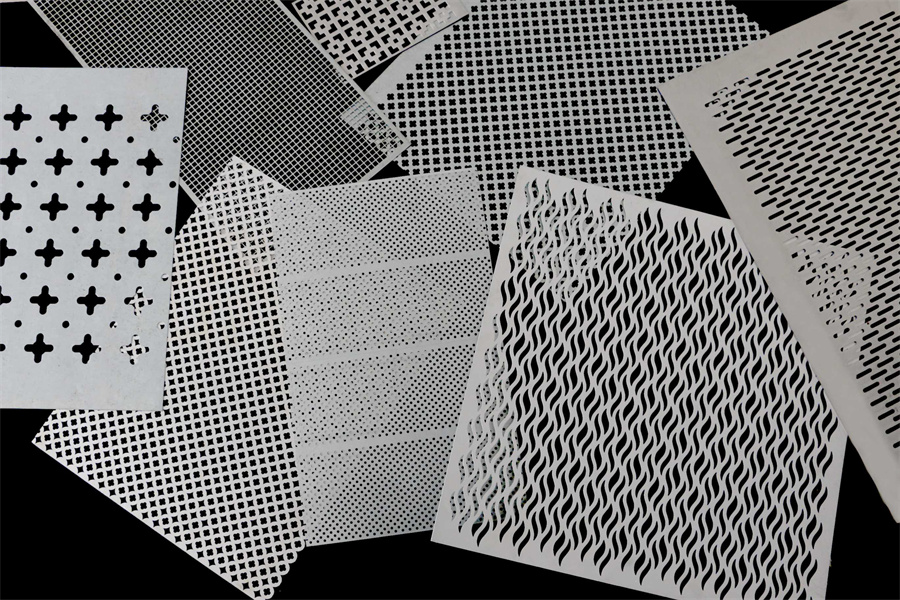

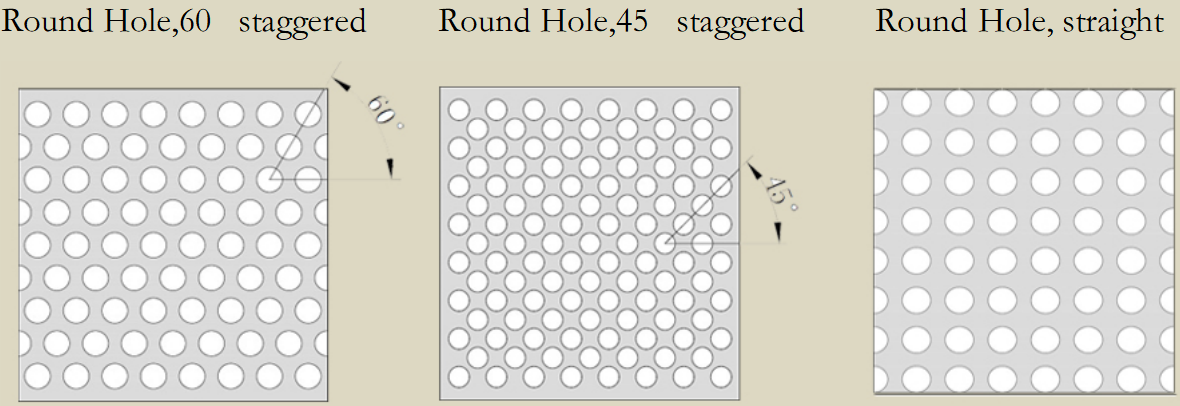

Hole Arrangement

Round hole are normally arranged in 3 types:

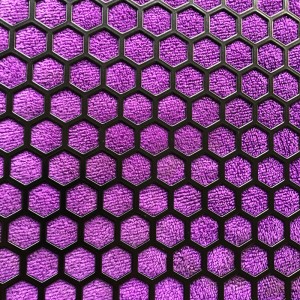

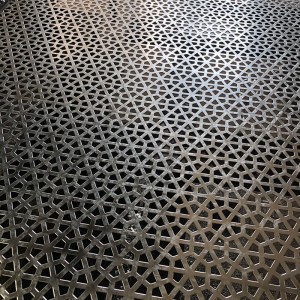

Other hole patterns and hole arrangement can be custom made.

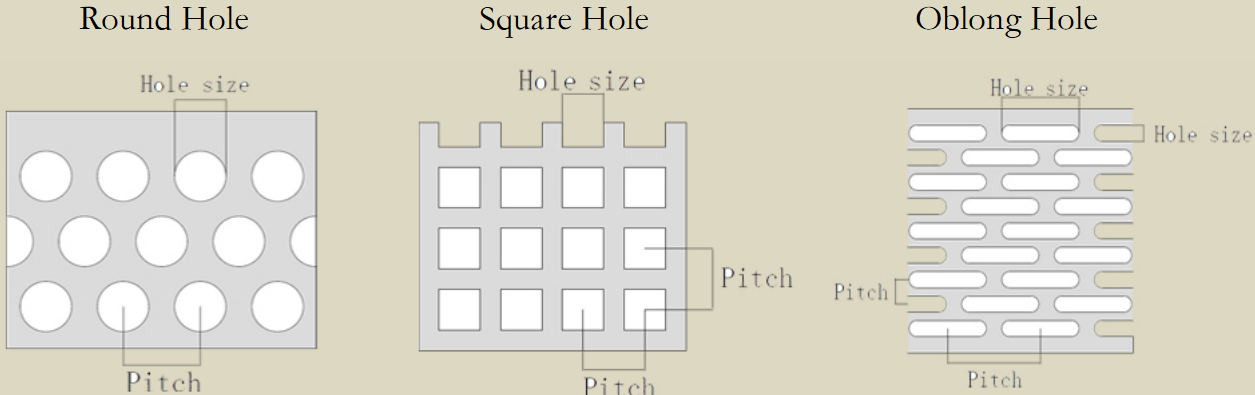

Hole size and Pitch

Other hole patterns and hole arrangement can be custom made.

Cutting & Folding

Perforated metal sheet can do cutting and folding after perforated.

Finish

Perforated metal sheet can do the following finish according to customers’ requirements.

Natural Finish

Most if the perforated sheet are required to be natural finish no matter what kind of material they are.

Oil Spraying

Some customers prefer the carbon steel perforated sheets to be oil sprayed to avoid the possible rusting because of the moisture during the long time sea shipping.

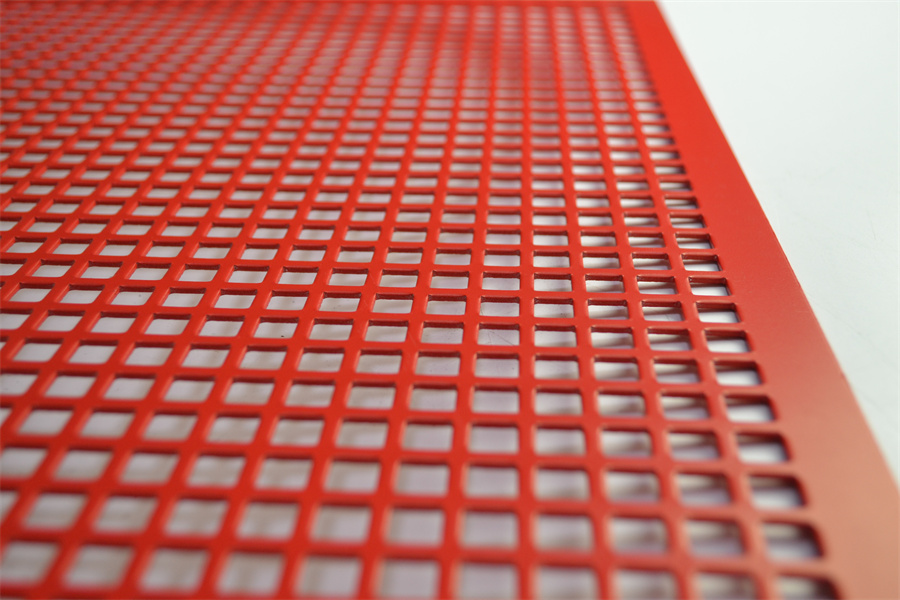

Powder Coating

Perforated metal sheet can do different colors powder coating,but minimum quantity might be required for some special colors.

Open Area

Open area is the ratio between the total area of the holes and total sheet area,normally it is expressed by percent,for example for a perforated sheet with the following specifications:

Round hole 2mm hole size,60 degree staggered,4mm pitch,sheet size 1mX2m.

According to the above information and based on the formula.we can get the open area of this sheet is app 23%,it means the total holes area of this sheet is 0.46SQM.

Related Products

Quality First, Safety Guaranteed